Manufacturing Technicians set up, run and monitor (non-chemical or non-biochemical) manufacturing processes to transform individual parts, sub-assemblies, and materials using machining, cutting, assembling, 3D printing, bolting, welding, forging, etc into distinct products (cars, phones, TVs, computers, cans, and machine tools) often on an assembly line.

Their workplace resembles a typical factory, with machine tools, assembly lines, robots, and conveyor belts. Manufacturing technicians typically have some training in manufacturing, production, industrial engineering or sometimes mechanical engineering.

They often use a blend of technical and mechanical skills to do their job. They work in industries such as:

- car manufacturing

- machine tool manufacturing

- consumer electronics

- computer or cellphone manufacturing

- aerospace

- light or heavy engineering

- battery and solar cell manufacturing

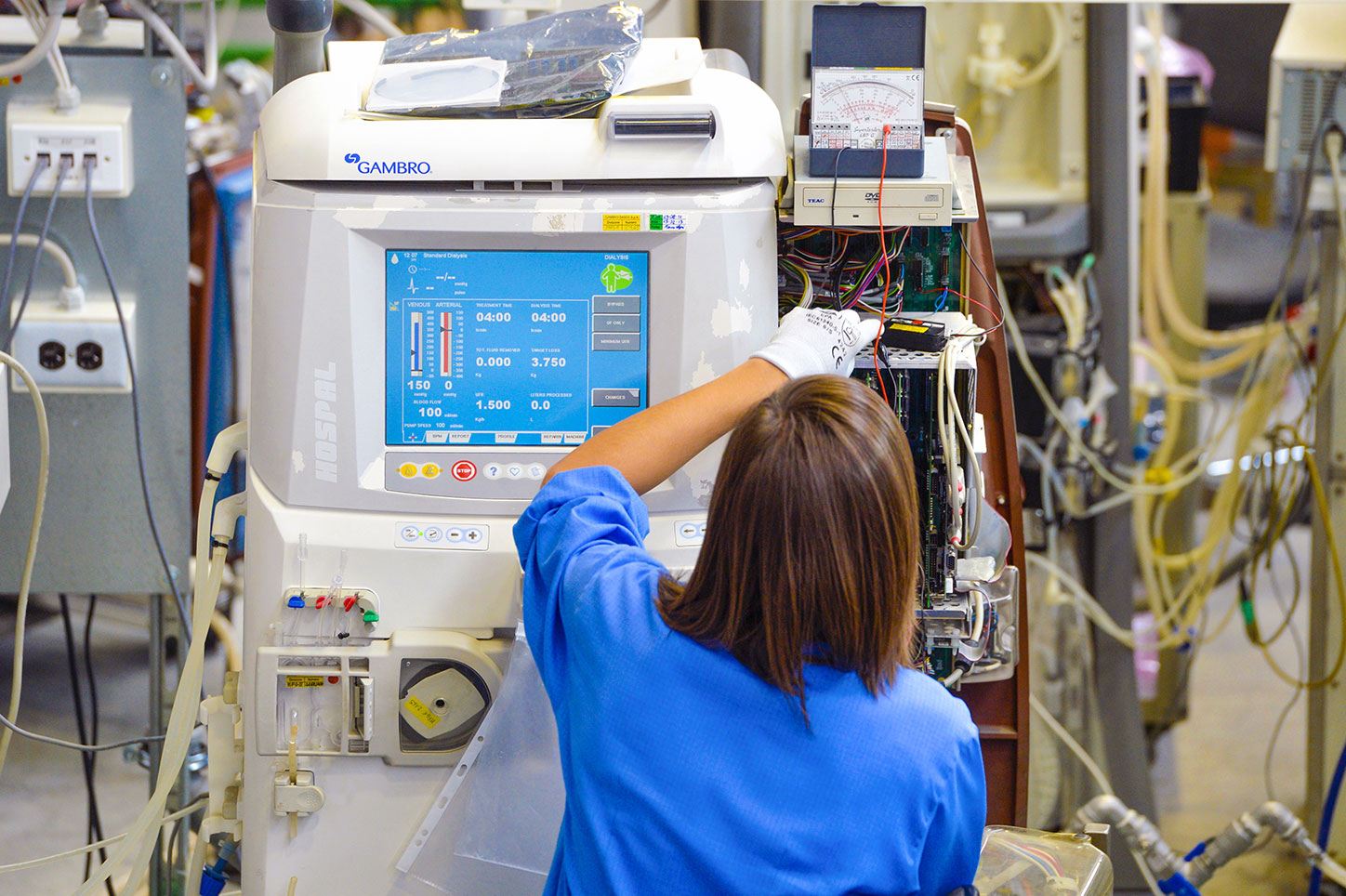

- medical device manufacturing

- later stages (fill finish/packaging) of pharmaceutical manufacturing

According to the BLS 2022 report on Mechanical Engineering Technicians, (closet role), the median average wage is $29.80 per hour, and the median average salary of $69,990 per year.

Entry-level salaries range from €35,000 – €45,000 plus overtime, bonuses and allowances. (Based on Morgan McKinley Irish Salary Calculator)

BTW, if you are interested in a career in the Medtech or Pharmaceutical manufacturing industries or are considering upskilling for a better job or a promotion, check out our range of pharmaceutical courses.

Manufacturing Technician vs Process Technician

There seems to be a huge amount of confusion between manufacturing technicians and process technicians.

Let’s take a look at the difference.

Manufacturing Technicians work in Discrete Manufacturing – This uses (non-chemical or non-biochemical) processes such as melting, casting, rolling, forging, milling, turning (on a lathe), sawing, laser, abrasive water jet or plasma cutting, grinding, shearing, punching, stamping, machine pressing, extruding, drawing (wire), injection moulding, assembling, bolting, screwing, welding, riveting and glueing to transforms individual or distinct parts, sub-assemblies, and raw materials (steel, copper, aluminium, wood) into a distinct product often on an assembly line.

Think car assembly – Toyota’s or Ford’s production line for its cars, washing machines, shipbuilding, cellphones, computers, ball bearings, screws, nuts and bolts, copper pipes, wire, electric motors, tanks, airplanes, syringes, medical pumps, scalpels, pacemakers, etc)

In a discrete manufacturing plant, you typically find, assembly lines, U-shaped assembly areas, conveyor belts, machine tools, CNC machine centres, 3D printing machines, industrial lathes, rolling mills, forges, stamping presses, extrusions machines, robots, welders (MIG, TIG, Induction, etc), pick and place robots, injection moulding machines, packing machines, air-powered assembly tools, painting, and finishing areas, etc.

Process Technicians work in Process Manufacturing – takes a formulation or recipe of ingredients and blends them together using a chemical or biochemical reaction, heat, pressure, refrigeration, fermentation, distillation, evaporation, pasteurisation, etc continuously or in a batch into a final product which is usually a liquid, powder or gas.

Think turning milk into baby formula, oil refining, gasoline, plastic, cheese, butter, paint or pharmaceutical manufacturing,

In a process manufacturing plant, you typically find, piping, pumps, tanks, flow valves, steam valves, temperature gauges, boilers, vessels, reactor vessels, crackers, distillation columns, heat exchangers, boilers, steam pipes, autoclaves, clarifiers, decanters, fluidised dryers, Program Logic Controllers (PLCs) PID (Proportional Integral Derivative) Controllers, conveyor belts, etc,

What Does a Manufacturing Technician Do?

A Manufacturing Technician’s role covers a broad range of responsibilities and may require a high degree of manual dexterity and the ability to operate factory machines, hand or power tools and use software to run computer-operated machinery.

Here are some of the more typical responsibilities;

- Setting up and operating production lines or different machines, running and monitoring the output of machine tools, a highly automated manufacturing cell or process. E.g. Injection moulding machines, 3D printers, stamping presses, CNC machine centres, CNC lathes, EDMs (electrical discharge machines), automated welding machines, transfer machines, transfer lines, tablet manufacturing or automated packaging machines.

- Working on or monitoring the output of an automated assembly line or assembly station.

- Apply lean manufacturing principles to eliminate the 8 deadly wastes in the production process or apply six sigma to reduce output variation.

- Know the manufacturing process in great detail, troubleshooting at an appropriate level and involving senior members of staff if/when they are not able to correct the problem.

- Monitor and check the product quality as they will be responsible for identifying when the process is deviating from the norm and taking action to correct it.

- Maintain accurate and clear documentation that proves that manufacturing is being carried out in accordance with both internal and external quality systems or regulations. It is important that procedures are followed, but it is also important that it can be shown and proved that procedures were followed.

- Keep equipment in good working order by performing regular inspections, cleaning, and servicing along with routine and preventative maintenance to make sure the machine or process never breaks down.

- Keep maintenance logs for all of the machines or processes they oversee, which requires proficiency in word processing and spreadsheet software.

- Provide regular productivity reports, and incident reports if an accident occurs.

- Follow strict internal protocols and Standard Operating Procedures (SOPs) as well as following current Good Manufacturing Practices (cGMP) when working in the pharmaceutical and medical device manufacturing industry.

A Manufacturing Technician may also be responsible for gathering of data from their part of the manufacturing process and reporting it to senior staff members (typically a Production or Manufacturing Engineer).

There is a large amount of responsibility given to individuals within these roles. Any deviation from these practices or any mistake made could have serious repercussions, resulting in potentially unsafe defective products or expensive destruction of batches.

Working as a Manufacturing Technician

Manufacturing Technicians spend little to no time at a desk and are almost always on their feet on the factory floor. Even when they are operating or monitoring a machine, they are still standing and alert. They spend most of the day they on their feet moving from work station to work station. In addition, the factory floor is often loud, and some factories may even require Manufacturing Technicians to wear ear protection.

In the pharmaceutical or medical device manufacturing industry, they usually work within a cleanroom environment so personal protective gear (including masks, clothing, footwear, and gloves) is required. This is both for their own safety and to maintain the integrity of the product by avoiding contamination.

Manufacturing Technician vs Manufacturing/Production Operator

We also see “Manufacturing/Production Operator” to describe an entry-level version of this role where they place heavy emphasis on strictly following processes, procedures and systems. Knowledge of manufacturing engineering isn’t generally a minimum entry requirement for an operator role. Some companies call this role:

- Manufacturing Team Member

- Manufacturing Operative

- Product Assembler

- Production Operator

- Production Operative

- Production Team Member

- Assembler

Becoming a Manufacturing Technician

This is a very broad role so the level of education and training required will vary dramatically depending on the complexity of the product and its manufacturing process, how automated the manufacturing process is, how stringent the quality control standards are, the company and its manufacturing philosophy and the volume of production; whether it’s low volume, batch or mass production.

A third level technical education or specialized vocational training is essential at some companies especially high-tech manufacturing e.g. semi-conductor, aerospace or medical device manufacturing. Typical subjects covered include:

- Manufacturing Engineering

- Quality

- Computer-Aided Design

- Electrical Sciences

- Engineering Science

- Engineering Mathematics

- Manufacturing Design of Fixtures

- Lean Manufacturing

- Manufacturing Automation

- Metrology

- Maintenance and Safety

- Advanced Manufacturing Processes

- Six Sigma Quality

- Manufacturing Process Planning

- Operations Management

- Robotics and Control

- Polymer Processing Technology

- Engineering Software Systems

- Project Management

But in contrast, there are plenty of mid-tech to low-tech and even a few high-tech manufacturers that provide on-the-job training to complete the tasks specific for each job role as necessary.

Some candidates do have either a Bachelor’s or Associate’s Degree in Engineering or a related field. These people are usually looking at the role of a Manufacturing Technician as a stepping stone to reach higher positions within the manufacturing industry.

Becoming a Manufacturing Technician in Medical Device and Pharmaceutical Manufacturing

The majority of roles tend to be in medical device manufacturing as there is a much broader use of discrete manufacturing. Pharmaceutical and biopharmaceutical manufacturing will also have roles but the majority (but not all) tend to be concentrated around packaging operations (Think running a highly automated packaging line).

If you want to get an entry-level role within the pharmaceutical or medical device manufacturing industry, check out our Conversion Course into Pharma. This program is the quickest way to learn all you need, to successfully move into an entry-level job. Depending on your previous qualifications and work experience, you may need to take our 37-week university accredited Certificate in BioPharmaChem program to get to the role of manufacturing technican.

If you already have significant experience working as a manufacturing technician and want to retrain to work in the pharmaceutical and medical device manufacturing industry, take our Good Manufacturing Practices (GMPs Training Course)

What Skills Do I Need?

The ideal skill set for someone moving into a Manufacturing Technician role includes:

- Attention to detail – there are often many steps involved in a process, must be familiar with the details of each. Must follow SOPs closely and must observe all features of the cleanroom environment thoroughly

- Alert – must be able to quickly identify when the manufacturing process is deviating from the norm

- Calm under pressure – must be able to confidently address problems if they arise, take appropriate action and involve others when needed

- Numerical skills – there can be formulas to follow and numerical factors to consider when following protocols and procedures

- Good communication skills – written skills are important to ensure clear documentation and verbal and listening skills are important to ensure efficient transfer of information between staff members (keeping in mind that these might be high-pressure situations when troubleshooting problems)

- Good computer skills – much of the documentation of manufacturing is done via computer systems

- CAD/CAM – ability to use or learn CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software

- Engineering Documentation – able to read and follow blueprints and other types of engineering documentation

- Measurement – ability in mathematics and measurement

- Lean Manufacturing Skills – must be able to identify and eliminate waste within the system

- Basic QA and QC Skills – such as ISO 9000, Six Sigma, Statistical Process Control, etc

Manufacturing Technician Salaries & Job Growth

Check out our Manufacturing Technician’s salary guide for “Euro” and “US Dollar” salaries local to you.

In the UK, the basic entry-level salary for a Process Technician is £25,870

Reference: Office of National Statistics

Manufacturing Technician Resume Tips

As with all resumes, it’s extremely important that you tailor your Manufacturing Technician resume to reflect the language used within the job advert. Where you have relevant experience or skills, use the words and phrases that the employer has used to describe them. Do not assume that someone will read similar wording and know what you mean.

Manufacturing Technician roles will typically be looking for the skills previously outlined:

- Attention to detail

- Alert

- Calm under pressure

- Numerical skills

- Good communication skills

- Good computer skills

For more help, check out resume templates and this list of 30 tips to improve your resume.

Manufacturing Technician Job Vacancies in Pharma/MedTech

For more information on currently available Manufacturing Technician roles, head to our jobs boards and select Production/Manufacturing in the “Jobs by Category” menu. We currently have jobs boards for Ireland and the UK.

24 Other Types of Pharma Job Roles

Manufacturing/Production

Engineering

- Process Engineer

- Manufacturing Engineer

- Instrumentation Engineer

- Project Engineer

- Automation Engineer

Maintenance

Quality

Science/Laboratory

Validation

Our Most Popular Programs and Courses

- Equipment Validation Training Course – For Starter Validation, CQV and C&Q Roles

- Pharmaceutical Validation Training Course – For More Senior Validation, CQV and C&Q Roles

- Computer System Validation Training Course

- GMP Training for the Pharmaceutical Industry

- View All 13 Pharmaceutical Industry Courses

About the Author

Donagh Fitzgerald

Head of Marketing & Product Development

Mechanical/Production Engineer

Donagh looks after the marketing and product development including the training and pedagogical elements of our programs and makes sure that all GetReskilled’s users can have a great online learning experience. Donagh has lived and worked in many countries including Ireland, America, the UK, Singapore, Hong Kong and Japan. Donagh has also served as the Program Manager for the Farmleigh Fellowship based out of Singapore.

Donagh holds Degrees in Production Engineering and Mechanical Engineering from South East Technological University, Ireland.

Claire Wilson

Content Marketing and Career Coaching

Claire runs GetReskilled’s Advanced Career Coaching Programme – our specially devised job hunting course that helps our trainees take that final step into employment by leading them through the job hunting process. She is extremely enthusiastic about helping people reach their final goal of employment in their new career path.

Claire has a BSc (Hons) in Medical Biology from Edinburgh University and spent 7 years working in the pharmaceutical and medical device industries.

Could I applied for part time form on education and when is the date?

Hi Mariana,

Could I clarify? Do you mean if you can take our programs and courses part-time?

Best wishes

Donagh

Is there a difference between “Manufacturing Technicians” and “Manufacturing Associates”?

Generally speaking, a manufacturing technician’s job would be more technically involved and probably better paid than that of a manufacturing associate.

However, different companies can call the same job different things, and the same job title can mean different things in different companies. It can be frustrating but the only way to get past this is to read job adverts.

Hi, my name is Abhijith Gopakumar Sheeja. I did mechanical engineering in India and completed MBA in project management in Ireland. I wish to work in the pharmaceutical field but I am confused with which course would be suitable for me and that would help me to get a work permit.

Hi Abhijith,

The majority of roles for mechanical engineers in pharma and medical device manufacturing are in:

For project engineering roles, you could bolster your application with a relevant project management qualification.

For plant engineering or maintenance type roles, you are probably going to need some retraining but this is going to depend on your experience.

For more mechanical design or combination product-focused roles, your current qualifications may be enough although additional training especially in GMPs or combination products would definitely bolster your application.

Another option would be to retrain for validation roles as your background in engineering design, plant engineering, fluid dynamics and even thermodynamics are all relevant to this field.

Apart from the general “Maintenance Engineer” or “Plant Engineer” job titles, here are some typical job titles we often see advertised.

Could you check out this link for more detail on the types of jobs that mechanical engineers could find in the pharmaceutical and medical device manufacturing sector? https://www.getreskilled.com/engineer/