Don’t just learn about Equipment Validation… learn to do Equipment Validation

Would you expect to get fit by watching a personal trainer work out?

Would you expect to learn to drive a car by watching an instructor take a drive?

Would you expect to learn a new language by watching others speak it?

Of course not.

And you don’t learn Equipment Validation by sitting through a lecture – or guessing the right answer on a quiz.

You learn it by doing it.

Fill out a 120-page blank IQ OQ PQ protocol

For your End of Module Assignment, you will replicate what your validation manager would ask you to do in a real work setting.

You will populate and execute a 120-page IQ OQ PQ protocol to qualify a Clean-In-Place (CIP) system. We will guide you step by step using a template taken from an actual pharmaceutical project.

The protocol will include;

- Product characteristics – what your system is looking to achieve/produce

- Production equipment – the equipment necessary

- Test scripts and methods – the steps involved in conducting a test

- Test parameters and acceptance criteria – defining acceptable test results

- Test checksheets – documenting and recording the test results

- Final approval – confirming that the validation process was successfully carried out

Our Chemical and Validation Engineers will review your protocol and provide written feedback.

Prove your Expertise at a Job Interview

Take your completed IQ OQ PQ Protocol to a job interview to demonstrate your expertise.

Entry Requirements

You must have one of the following backgrounds or skills:

- Commissioning & Qualification Experience: In any industry, such as Oil and Gas, Food Manufacturing, etc.

Or - Plumber/Pipefitter/Pipe Welder (e.g. high purity pipe fitter and orbital welder): You can interpret P&IDs and pipe skids and are tired of working outside on freezing cold construction sites.

Or - GMP Manufacturing Experience: Over 18 months of factory floor experience.

Or - Quality Assurance or Quality Control in Pharma: You are worried about signing off on qualification documents you don’t fully understand.

Or - Engineer or Scientist: Chemical, process, petroleum, project, mechanical engineer, or a laboratory scientist.

Or - Validation Professional: You already work in qualification/validation (e.g., mechanical contracting company doing high-purity pipework installations) but lack formal training on IQ OQ PQ protocols.

What validation, CQV and C&Q jobs could I get hired for?

STEP 1, you take this “Equipment Validation Course” to retrain for the following roles;

- Validation Technician – Some pharma companies call this role:

- Associate QA Validation Specialist

- Equipment Validation Specialist

- QA Validation Associate

- QA Validation Specialist

- CQV Specialist – Some pharma companies call this role:

- CQV Junior Engineer

- C&Q Specialist

- C&Q Junior Project Manager

Career Paths

With validation, CQV and C&Q roles, you could work directly for:

- pharmaceutical companies on in-house projects

- engineering consultancies on contractors as part of a project team on small to large capital projects

STEP 2, then take our Pharmaceutical Validation Training Course – For Senior Validation Roles to get a level 7 university accredited “Certificate in Validation” from Technological University Dublin, Ireland and a more interesting job with a higher salary such as:

- Validation Engineer

- CQV Engineer

- Senior Validation Specialist

- C&Q Technician

Enroll in this program to learn…

- How to prioritize which parts of the equipment system are critical to qualify and which parts are not, using component impact assessments and risk management tools.

- How to read and interpret engineering documents such as P&IDs, Piping Isometrics, and Electrical Loop Drawings used to define the equipment system.

- How the intent of a process (like maintaining the product at the required temperature) is linked to the equipment used for this purpose.

- The tests and functional test scripts needed to confirm that the installed equipment meets the User Requirement Specifications (URS).

- How to use a traceability matrix tool to make sure all requirements in the URS are tested in the protocol.

- How to qualify equipment, instruments, piping systems, and automation controls.

- How to document all of these steps in a 120-page plus equipment qualification protocol which you will complete as your end-of-module assignment.

You’ll produce a number of deliverables throughout the program including…

- Complete 2 Quality Risk Management workshops on:

- Fault Tree Analysis (FTA)

- Failure Mode Effect Analysis (FMEA)

- Complete 5 Equipment Qualification Protocol workshops on the following to prepare you to populate your own protocol:

- Component Level Impact Assessment

- Equipment Installation Verification

- Piping Installation Verification

- Instrument Installation Verification

- Functional Verification Test

- Complete 12-question booklets (one for every week’s worth of content) which will summarise what you have learned for the week and ensure you retain and understand the information.

End of Module Assignments

- Complete a 1,500 word technical report on the GMPs that are required to consistently manufacture safe medicines, vaccines, and medical devices for patients.

- Populate a 120-page plus IQ OQ PQ protocol for a Clean-In-Place system. The protocol will include;

-

- Product characteristics

- Production equipment

- Test scripts and methods

- Test parameters and acceptance criteria

- Test checksheets

- Final approval

Complete 2 modules over 15-weeks

Module 1 – Manufacturing Safe Medicines and Medical Devices (GMP) (Weeks 1-5)

In this module, you’ll learn about the systems used in pharmaceutical manufacturing. You’ll learn about the rules and regulations such as Good Manufacturing Practices (GMPs) that you need to follow.

Module 2 – Commissioning and Qualification (IQ OQ PQ) of Equipment and Systems (Weeks 6-15)

In this module, you will learn to fill in a 120-page Qualification Protocol to qualify a Clean-In-Place system. You will also learn to read and interpret P&IDs, Piping Isometrics & Electrical Loop Drawings used to develop qualification protocols. And you’ll also learn how to qualify equipment, instruments, piping systems, automation controls, and building facilities.

So what is equipment validation?

Equipment validation which is more commonly referred to as equipment qualification is the regulated and documented act of proving that a mechanical, piping, software system or subsystem is installed correctly, operates as required and performs as expected under load. Qualification is part of the larger process of Pharmaceutical Validation is normally used for:

- Equipment

- Ancillary systems

- Instruments

- Utilities ((air, water, steam)

Equipment qualification makes sure that a facility and the equipment in it, function as required so that it can be approved by the regulatory agencies that have jurisdiction over that facility. It makes extensive use of IQ OQ PQ or Installation Qualification, Operational Qualification, and Performance Qualification.

These sequential steps are collated in an Equipment Qualification Protocol which is a written plan that states how qualification will be conducted including test parameters, product characteristics, production equipment, and decision points on what constitutes an acceptable result.

The protocol is written for each critical system and outlines the steps and measurements required, what proof is needed, what the expected outcomes are, and what should be done if actual outcomes deviate from this.

Entry-level equipment qualification roles tend to focus on populating or executing a pre-written equipment qualification protocol.

As you get more experience and develop a more in-depth understanding of what you are testing, you will begin to start writing and developing these test protocols.

Need more detailed information?

Watch this video on a validation engineer’s role!

For a great insight into validation roles from someone actually in the job, check out this video from the About Bioscience website, produced by the North Carolina Association for Biomedical Research (NCABR).

Hear from people who’ve taken this equipment qualification course

Colin Lane

Previous background:

Med device manufacturing

“Validation – A career move to tell your friends about”

“I would say to anybody out there, if you’re thinking about doing this validation course, just go for it. Do it.

There’s a great opportunity within the course to learn. There’s a lot of detail about what goes on in the industry, on the floor, and how things happen. Focus just as much on learning to actually educate yourself as much as passing exams.

Hear more and read how Colin moved from medical device manufacturing into validation.

Charles O Neill

Previous background:

Pipefitter/Plumber

“With hard work and determination, you can achieve your goal”

“As a pipefitter/Plumber who worked within the pharmaceutical industry for the last 20 years, this program gave me the tools I required for a career change and to upskill for a job in pharmaceutical manufacturing. Without this course, I don’t think I would have achieved this. I am happy to say that I have been successful in my employment search.

It is worth the challenge and with hard work and determination, you can achieve your goal.

Regina McNamara

Previous background:

Professional Painter

“I can study around work and family commitments”

Studying online is working well for me as I study around work and family commitments.

I would recommend this course to anyone that wants a new career in the Pharmaceutical and Medical Device Manufacturing industry.

Your 10 or 15 week class schedule

Note: If you’ve worked in a GMP Regulated Pharmaceutical Manufacturing Environment, you are exempt from the first 5 weeks (Module 1) of the program. You also get a price reduction.

15-Day Fast Track Option Available – For an additional cost, you can request an immediate start and complete the 2-module 15-week program in 15 days. This is going to be tough but your course leader will check your progress every morning and follow up with you to keep you on schedule. START within 24 working hours upon receipt of payment.

Module 1 – Manufacturing Safe Medicines and Medical Devices (GMP) (Weeks 1-5)

Module 2 – Commissioning and Qualification (IQ OQ PQ) of Equipment and Systems (Weeks 6-15)

This module was developed in consultation with the pharma industry including Pfizer and MSD.

Delivered by a practicing industry expert

Dr. Joe Brady

Full-Time Validation Lead

Lecturer, Technological University Dublin, Ireland

Senior Associate, GetReskilled

Dr. Joe Brady is a full-time practicing Validation Lead and an assistant lecturer with Technological University Dublin (TU Dublin), in the School of Chemical and Pharmaceutical Sciences. Joe is a certified trainer and highly experienced in competency-based training. He designs and prepares educational modules and full academic programs ranging from MSc, MEngSc. BSc, to Certificate level, for a range of academic institutions.

He is also a supervisor for MSc/MEngSc and Ph.D. theses. Joe has over twenty years of project experience in the pharmaceutical, biopharmaceutical, and medical device industries in Ireland, Singapore, China, The Netherlands, France, and the USA.

Hear from people who’ve taken this equipment qualification course

Mehmet Hascan

Previous background:

Technical Support

“Material was delivered in an engaging, interesting and supportive way”

The administration staff and lecturers at Getreskilled are first class and the course material was delivered in an engaging, interesting and supportive way.

I have now been working at Johnson and Johnson Vision Care as Validation Engineer in Limerick and I look forward to put what I have learned into practice.

Sharon Egan

Previous background:

Food Manufacturing

“Structurally well planned with the opportunity for practical application”

I found it to be interesting, structurally well planned with the opportunity for practical application of the course modules through various assignments.

I have worked in the Medical Device/Pharmaceutical and Food industries and found the course to be extremely relevant to all industries.

Start your application

Contact Details For This Course

Geraldine Creaner

How We Deliver Our Online Courses without ZOOM Classes

With every GetReskilled ONLINE program;

- Centralized Platform: We use one platform (Moodle) where you can log into your classroom anytime. Each week, you’ll watch videos and complete quizzes, tests, interactive activities, and projects. The course materials are available 24/7, so you don’t have to be online at a specific time. There are NO ZOOM classes. Study anywhere, anytime, such as after the kids are in bed or on the weekend.

- Flexible Schedule: Your working schedule may be unpredictable, so we offer flexible delivery. You can slow down, speed up, or pause the program as needed.

- Weekly Progress Checks: We release one week’s worth of material at a time and manually check your activity logs at the end of each week to ensure you are keeping up with your work.

- Dedicated Course Leader: You’ll have a course leader who will email or call you if it looks like you’re falling behind. They will help you develop a study plan to get back on track and finish the course.

All of this helps us to spot any potential issues early and helps you completely finish the program.

Add On Program – 5-Week Advanced Career Coaching – Open Your Eyes to Modern Job Hunting

This is a practical course, not a theoretical one. There is no “filler” content. Each and every task is specially designed to take you one step closer to the job you want in a structured way.

The course is assessed using a mock application for a real job advert. You’ll complete a 9-step application process simulation for a BioPharma/MedTech job, using the relevant tools and techniques.

“I never realised how much I didn’t know”

That’s the most common feedback we get when people finish this programme. And it really doesn’t take that long to get that new knowledge and start putting it to good use…

Week 1 – Get a comprehensive understanding of BioPharma/MedTech Industry and figure out jobs you can do

Week 2 – Practice skills assessments, write, rewrite and customize CVs and resumes

Week 3 – Speculative job applications and how to research jobs available

Week 4 – Social Media, networking and interview preparation

Week 5 – End of Module assignment. Complete a 9-step application process simulation for a BioPharma/MedTech job, using the relevant tools and techniques.

On completion of this module you’ll be able to:

- Discuss your local BioPharma/MedTech manufacturing industry

- List the departments and job roles where your skills are best suited

- Understand your current skill set and how to discuss that with employers

- Network effectively both on and offline

- Write a CV and cover letter that are highly tailored to a job advert

- Write a speculative application and have a list of local companies appropriate for such an application

- Prepare for an interview

You’ll also have access to a program advisor who is there to offer support and guidance, offer personalized feedback and provide additional resources in any areas you need a little extra help.

At the end of the course, you’ll have confidence through a more strategic approach to job hunting. You’ll have a complete tool kit for modern job hunting.

Meet Claire

Claire runs GetReskilled’s Advanced Career Coaching Program – our specially devised job hunting program that will help you find a job.

Earn a Certificate of Award in “Commissioning & Qualification of Equipment and Systems”

Earn by successfully populating a 120-page IQ OQ PQ template to qualify a Clean-in-Place System and get a Certificate of Award in Commissioning & Qualification (IQ OQ PQ) of Equipment and Systems.

Add details of your certificate to your CV/Resume or your LinkedIn profile.

13 frequently asked questions

Price

$799/month

For 5 months

Or $3,499 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

$2,899

Save $600

15 Day Fast Track Option with Priority Support

$4,999

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

€699/month

For 5 months

Or €3,199 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

€2,699

Save €500

15 Day Fast Track Option with Priority Support

€4,499

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

£649/month

For 5 months

Or £2,799 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

£2,299

Save £500

15 Day Fast Track Option with Priority Support

£3,999

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

Price

€699/month

For 5 months

Or €3,199 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

€2,699

Save €500

15 Day Fast Track Option with Priority Support

€4,499

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

$799/month

For 5 months

Or $3,499 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

$2,899

Save $600

15 Day Fast Track Option with Priority Support

$4,999

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

£649/month

For 5 months

Or £2,799 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

£2,299

Save £500

15 Day Fast Track Option with Priority Support

£3,999

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

Price

£649/month

For 5 months

Or £2,799 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

£2,299

Save £500

15 Day Fast Track Option with Priority Support

£3,999

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

€699/month

For 5 months

Or €3,199 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

€2,699

Save €500

15 Day Fast Track Option with Priority Support

€4,499

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

$799/month

For 5 months

Or $3,499 in Advance

Reduced Price After Skipping First 5 Weeks. Only available if you’ve GMP Pharmaceutical Manufacturing Experience

$2,899

Save $600

15 Day Fast Track Option with Priority Support

$4,999

- Complete this program in 15 days.

- Your course leader will check your progress every morning and follow up with you to keep you on schedule.

- START within 24 working hours upon receipt of payment.

Application Process

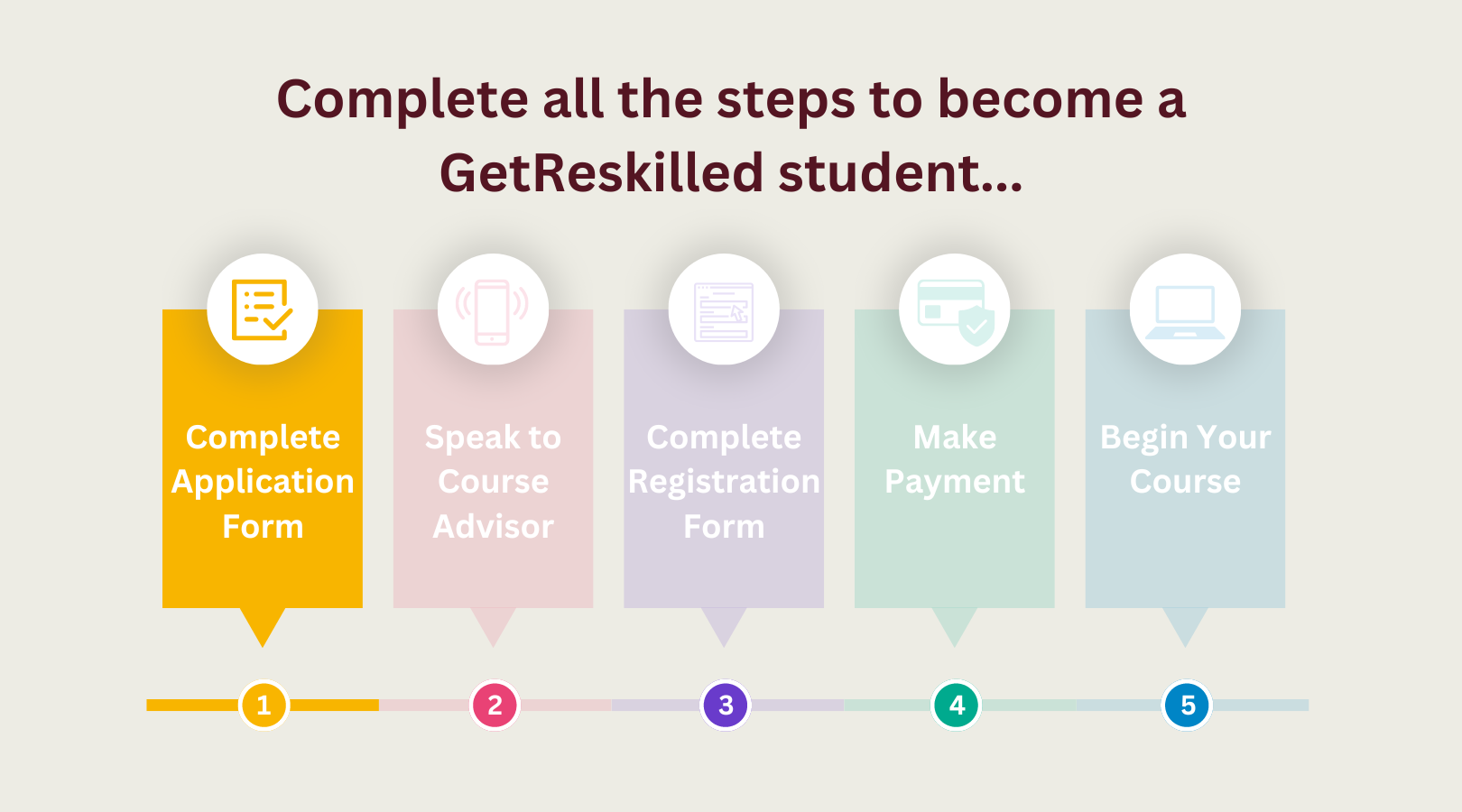

The application process is an extremely easy 5 step process:

- Complete the application form – click on the big red “Apply NOW” button.

- Speak to a course advisor – they will let you know if you’re a good fit for the program and answer any questions you have.

- Complete the registration form – you’ll be sent this by email after you’ve spoken to a course advisor

- Make payment – successful applicants will then make payment. It is only at this stage that a place on the course is secured. Payments can be made in full or set up as monthly instalments to fit your budget.

- Begin your course!

We’ll be right there with you every step of the way. If you have any questions, please get in touch!

Application Deadline: Wednesday 9th July

Program Starts: 16th July

Contact Details For This Course

Geraldine Creaner

Got more questions?

Hi, I’m Donagh Fitzgerald. Chat with me live anytime – just click the blue chat bubble in the bottom-right corner of the page.

I’m online Monday to Friday during working hours (Irish/UK time).

If I’m away from my desk, leave a message and I’ll get back to you as soon as I can.

Or you can fill out the form below and we’ll reply within one working day.