A Calibration Technician is responsible for the calibration, routine inspection, testing, maintenance and repair of instruments, meters, gauges and other testing and measuring equipment. The goal of a Calibration Technician is to ensure the accuracy and precision of the measurements taken using this equipment.

According to the U.S. Bureau of Labor Statistics 2023 report on Calibration Technicians, the median average wage is $32.33 per hour and a median average salary of $67,360 per year.

Some Companies Might Call This Role…

- Electrical and Instrumentation Technician

What is Calibration?

Calibration is the process by which instrumentation, gauges, meters and other testing equipment are set up, checked and maintained to ensure they continue to give accurate, precise and reliable results.

A huge range of equipment including manufacturing instruments, devices and gauges can require calibration. In scientific research or manufacturing environments, this equipment will be used to monitor things such as temperature, humidity, pressure, light intensity, voltage, mass etc.

The specific equipment to be maintained will vary between roles, depending on the specific place of work and what is being manufactured.

The work of a calibration technician is vital to successful scientific research and manufacturing. Without precise calibration, the accuracy and precision of readings, actions, and output of equipment cannot be assured.

In highly regulated industries such as pharmaceutical or medical device manufacturing, it is essential. There are strict protocols to be followed and precise documentation to be completed to prove that calibration activities are carried out correctly.

Calibration technicians are routinely required throughout the manufacturing cycle and, as a result, shift work is generally required.

What Does a Calibration Technician do?

A Calibration Technician will routinely test equipment and instruments to check that their readings and output meet expected results. If a deviation is found, that piece of equipment will be further analyzed, adjusted or repaired as necessary.

The specific tasks carried out will vary depending on the specific role but, activities can include:

- Installation of new or repaired equipment or parts

- Routine testing, calibration, and monitoring of equipment

- Analysis and interpretation of testing result data

- Troubleshooting when results fall out-with the expected ranges

- Repair of equipment as necessary

- Ordering of parts

- Compilation of reports for facility management

Where Does a Calibration Technician Work?

Calibration Technicians work across all industrial sectors such as scientific research, car manufacturing, electronics, shipbuilding, light and heavy engineering, aerospace, pharmaceutical, food and dairy, chemical and petrochemical manufacturing, agriculture processing, mineral processing, medical device manufacturing, etc and make sure the equipment is regularly serviced and calibrated to industry standards.

Becoming a Calibration Technician

An associate-level or ordinary-level degree is a typical requirement in mechanical, electrical electronic engineering. Typical subjects include metrology (the science of measurement), manufacturing/industrial engineering, instrument technology and electronics.

In addition, those who have served an electrical apprenticeship can also cross-train into instrumentation/calibration roles. Experience in a manufacturing environment and training is preferred for some roles. Companies will often provide in-house training on the specific equipment used.

If you are working in a biotechnology, genetics, medical research or microbiology laboratory you may require a basic understanding of the scientific principles of the labs with which you will work.

A full degree or a postgraduate course is generally not necessary as this is an applied science.

If you already are working as a calibration engineer and wish to retrain to work in the same job within the pharmaceutical or medical device manufacturing industry, check out out GMP Training for Beginners program.

Accuracy vs Precision

These are two terms you will always hear of when talking about a calibration technician’s job. So what are they?

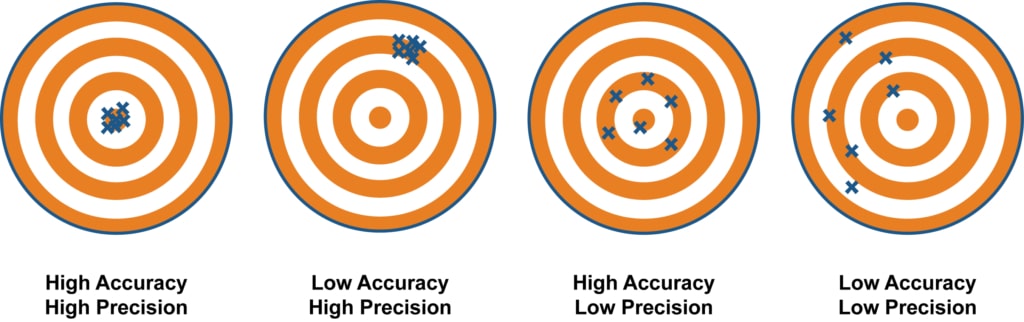

Precision and accuracy are two ways that engineers and scientists think about measurement error.

Accuracy refers to how close a measurement is to the true or accepted value.

Precision refers to how close measurements of the same item are to each other and is independent of accuracy. That means it is possible for a measuring instrument to be very precise but not accurate. In this situation, the instrument needs to be calibrated.

It’s also possible for an instrument to be accurately calibrated without it being precise. The highest quality measurements are both accurate and precise.

What Skills Do I Need?

The skills required to be a successful Calibration Technician include:

- Metrology – this is the science of measurement. You should have a deep understanding of this subject and the difference between accuracy, precision and repeatability.

- Manual Dexterity – professionals in the area must have excellent hand-eye coordination and be able to perform potentially tricky actions quickly and correctly.

- Communication – both written and verbal communication skills are necessary. May be required to report outcomes of tests to engineering department staff, routinely liaise with colleagues to schedule testing and repair, compile reports for management and deal directly with suppliers for replacement equipment or parts

- Attention to detail – precision is essential in this role, the smallest details have to be noted and acted upon when necessary. Must also follow the SOPs for testing and calibration of equipment in an extremely strict manner

- Coordination – will be working with a range of manufacturing equipment, conducting tests in strict adherence to SOPs and protocols

- Analytical skills – must be able to take raw test data and analyze it accurately, reaching sound conclusions. Must also be able to critically analyze problems and come up with innovative solutions when required

- Team working – must work closely with colleagues to define testing routines, protocols, and schedules

- IT skills – data entry and database use is an important part of the job and must be done in accordance with any internal SOPs and external regulatory protocols

Calibration Technician Salaries & Job Growth

Check out our salary guide for Calibration Technician salary information local to you.

Calibration Technician Resume Tips

As with all resumes, it’s extremely important that you tailor your Calibration Technician resume to reflect the language used within the job advert. Where you have relevant experience or skills, use the words and phrases that the employer has used to describe them. Do not assume that someone will read similar wording and know what you mean.

Calibration Technician roles will typically be looking for the skills previously outlined:

- Communication

- Attention to detail

- Coordination

- Analytical skills

- Team working

- IT skills

For more help with your resume, check out these templates and this list of 30 tips to improve your resume.

Calibration Technician Job Vacancies

For more information on currently available Calibration Technician roles, head to our pharmaceutical jobs board for Ireland and our pharmaceutical jobs board for the UK and select Maintenance in the “Jobs by Category” menu.

24 Other Types of Pharma Job Roles

Manufacturing/Production

- Process Technician

- Process Operator

- Manufacturing Technician

- Production Operator

- Packaging Operator

- Production Supervisor

Engineering

- Process Engineer

- Manufacturing Engineer

- Instrumentation Engineer

- Project Engineer

- Automation Engineer

Maintenance

Quality

Science/Laboratory

Validation

Our Most Popular Programs and Courses

- Equipment Validation Training Course – For Starter Validation, CQV and C&Q Roles

- Pharmaceutical Validation Training Course – For More Senior Validation, CQV and C&Q Roles

- Computer System Validation Course

- GMP Training for the Pharmaceutical Industry

- View All 13 Pharmaceutical Industry Training Courses

About the Author

Donagh Fitzgerald

Head of Marketing & Product Development

Mechanical/Production Engineer

Donagh looks after the marketing and product development including the training and pedagogical elements of our programs and makes sure that all GetReskilled’s users can have a great online learning experience. Donagh has lived and worked in many countries including Ireland, America, the UK, Singapore, Hong Kong and Japan. Donagh has also served as the Program Manager for the Farmleigh Fellowship based out of Singapore.

Donagh holds Degrees in Production Engineering and Mechanical Engineering from South East Technological University, Ireland.

Claire Wilson

Content Marketing and Career Coaching

Claire runs GetReskilled’s Advanced Career Coaching Programme – our specially devised job hunting course that helps our trainees take that final step into employment by leading them through the job hunting process. She is extremely enthusiastic about helping people reach their final goal of employment in their new career path.

Claire has a BSc (Hons) in Medical Biology from Edinburgh University and spent 7 years working in the pharmaceutical and medical device industries.

Post Your Comments Below