Our BSc (Hons) degree programme is delivered completely online with a part-time schedule that’s fully flexible. You have complete control over when and where to study. You don’t have to give up your work, or your home life commitments, no matter what they are, you can you can make this work for you.

You don’t need an access course or A-levels and we have multiple start dates throughout the year. There’s no UCAS application or personal statement writing – you deal with us directly and talk to your own course coordinator from day 1.

You get all the benefits of distance learning with the confidence of a degree from a brick-and-mortar university, as the programme is accredited by the University of South Wales.

We put mature students at the heart of everything we do

We are the right choice for you if:

- You want the convenience of distance education with the reliability of a bricks and mortar university

- You want to get a degree on your terms, with a course that is designed especially for mature students

- You want a “personal trainer” who will make sure you get the qualifications you are looking for

- You want regular course start dates so you don’t have to waste months waiting

This course is right for you if:

- You don’t want to have to complete an access course just to be eligible to apply to university

- You don’t want to have to apply through UCAS and compete with 18-year-olds

- You don’t want the future of your education to rest on a personal statement

- You don’t want the traditional university experience an 18-year-old is looking for

Here are the 9 things you’ll find on this page…

(you can click through to any of these sections if you want, and if there is anything we haven’t answered for you, make sure to email us on geraldine@getreskilled.com )

1) Why this BSc (Hons) degree is a great choice for mature students

Navigating the path back to university as mature student is really tough. It often means trying to fit yourself into a box that was built for 18-year olds and is not designed for you, your needs or commitments.

At GetReskilled, we don’t take new school leavers. We are experts in the adult learning experience. We’re focused on providing an outstanding service tailored to mature students.

We have teamed up with the University of South Wales to deliver a BSc degree programme that is specifically for mature students. And because that’s all we do, we’re really good at it…

- You’ll get a dedicated course coordinator who’ll be your single point of contact for any questions you might have

- They’ll check in with you every week to make sure you’re staying on track and coping with the coursework

- You’ll be treated like an adult and given tailored support to meet your specific needs

- We offer monthly payments to allow you to spread the cost of your education

The traditional university experience doesn’t suit everyone but we don’t think that’s a reason you should miss out on the chance of fulfilling your potential and earning a BSc (Hons) degree.

2) GetReskilled and University of South Wales – A team you can trust

GetReskilled are a niche education company that specialises in helping mature students get the academic qualifications they want.

That’s all we do – so we’re really good at it.

We’ve won education awards, we’ve won pharma industry awards and we even placed 2nd in a European vocational training award. Our BSc (Hons) degree programme was developed in conjunction with some of the world’s biggest pharma companies (including Pfizer and MSD) and it’s delivered by highly respected working industry professionals.

We don’t say that to brag.

We say it so you know that when you choose GetReskilled, you’re choosing a team and a programme that you can trust.

We’ve been doing this for 15 years and have trained over 5,000 people. We only take a select number of individuals into our programmes each year because we know that the key to your success is the individual attention you get before, during and after your studies with us. We know every student’s name and we’re as invested in your success as you are.

3) Entry Requirements

You need to meet ONE of the following criteria:

A-Levels Level 3 Qualification or

Higher

You are eligible for the programme if you have your A-Levels, or a Level 3 qualification or anything higher. This does not have to be recent. If you have ever done a Level 3 qualification or A Level you are eligible

OR

GCSEs Level 2 Qualification & Relevant Experience

You are eligible if you have your GCSEs or any level 2 qualification, & you work in manufacturing, healthcare, science, engineering, validation etc. If you have ever done a Level 2 qualification or GCSE Level you are eligible

OR

GetReskilled Conversion into Pharma Manufacturing Course

You are eligible if you have taken our 10-week Conversion Course into Pharma Manufacturing. Click here for more details on this programme.

Please Note: For non-native English speakers, applicants may need to take a Duolingo, IELTS, TOFEL or equivalent language

test for this course. See the FAQ at the bottom of the page for more details

4) How the degree works

Our BSc (Hons) degree programme is a unique combination of technical modules and skills-based modules that takes you from your current situation to opening a door to jobs that require a BSc (Hons) degree

The essential course details:

- BSc (Hons) degree, accredited by the University of South Wales.

- You will also graduate with a University Certificate (Level 4) after 1-year of study, and a University Higher Certificate (Level 5) after 2 years of study – meaning you can take a break from your studies and come back where you left off.

- Delivered entirely online

- 15 hours per week with fully flexible timetable – there are no Zoom classes or webinars so you decide when and where to study

- 4-years to complete 14-modules

- You don’t have to wait for the academic year to start in November, our next intake closes for applications on Wednesday 23rd July

5) Course syllabus

Please keep in mind as you read through the following module titles (and/or descriptions), that the pharmaceutical industry uses technical language that you probably won’t have heard before. This can make the content sound a little daunting.

So while it’s nice to see what you’ll be studying – you aren’t meant to understand it yet!

You’ll be taken through all new content in a very manageable way. New concepts are introduced gradually and with lots of explanation. You do not need any previous experience in the pharmaceutical industry or any science/engineering/maths qualifications to be perfectly capable of understanding the course content.

Year 1

Module 1 – Fundamentals of Pharmaceutical Manufacturing Technologies (PH1S082)

This will give you a broad understanding of current Good Manufacturing Practices (cGMPs) – the set of unique regulations that pharmaceutical and medical device manufacturers legally have to follow to make sure they’re making safe products.

Module 2 – Writing Skills Module

This module equips you with a high level of written communication skills. You’ll study this as you’re writing your end-of-module assignment for Module 1. Not only will it walk you through the writing process for that (ensuring that you present your ideas in a way that gives you the best chance of achieving great marks), it’s also a highly practical development of the writing skills you’ll need within your career.

Module 3 – Pharmaceutical Facility Design (PH1S083)

This will give you a strong grounding in the unique utility systems (e.g. air and water) that are used in a manufacturing facility and the quality systems that are used to make sure that products are safe and effective.

Module 4 – Job Hunting Skills / Career Development Skills

This second skills module is the one that really gives your job hunt and career development a boost. We’ll walk you through the job hunting process step-by-step, showing you how to really catch an employer’s attention with your application and how to confidently interview. Examples are given for the pharma industry but all you’ll learn here can be taken to a job hunt in any industry.

Module 5 – Fundamentals of Chemistry for the Pharmaceutical Industry (PH1S084)

This final module of first year will give you a foundation in the general chemistry used for the manufacture of medicinal products. You don’t need any previous science qualifications to be able to study this module.

Please note: This module is run as a group module (3 times per year) and you will be required to keep pace with the class during the running of this module. This is the only module that you won’t be able to control the pace of your study on.

Award: University Certificate

Lock away your learning with a “University Certificate (Level 4)”

At the end of this year, you will be awarded a University Certificate in Pharmaceutical and Medicinal Product Manufacturing from the University of South Wales, meaning if you need to pause your studies at this point (and come back later), you can.

Year 2

Module 6 – Commissioning & Qualification of Equipment and Systems (PH2S107)

Module 7 – Planning a Validation Strategy (PH2S108)

Module 8 – Project Management and Techniques for the Pharmaceutical Industry (PH2S106)

Award: Higher University Certificate

Lock away your learning with a “Higher University Certificate (Level 5)”

At the end of this year, you will be awarded a University Higher Certificate in Pharmaceutical and Medicinal Product Manufacturing from the University of South Wales, meaning if you need to pause your studies at this point (and come back later), you can.

Year 3

Module 9 – Design and Operation of Cleanrooms (PH3S107)

Module 10 – Regulation for the Manufacture of Combination and Device Products (PH3S108)

Module 11 – Mathematics and Statistics for the Pharmaceutical Industry (PH3S109)

You’ll now be three quarters of the way through your 4-year BSc degree programme with GetReskilled and the University of South Wales

Year 4

Module 12 – Fundamentals of Physical Chemistry and Chemical Safety for the Pharmaceutical Industry (PH3S110 )

Module 13 – Process Development and Technology Transfer (PH3S111)

Module 14 – From URS to PQ – A practical validation strategy (PH3S112)

Award: BSc Honours Degree

At the end of this year, you will graduate with a BSc (Hons) in Pharmaceutical and Medicinal Product Manufacturing from the University of South Wales.

6) Why online with GetReskilled increases your chance of success

We do things a little differently at GetReskilled…

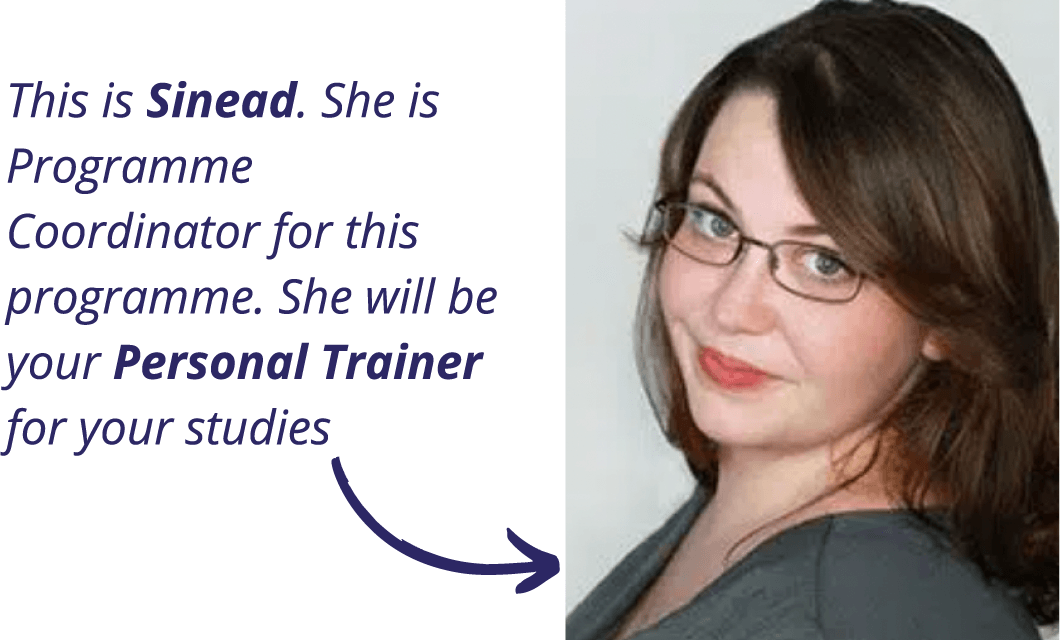

Single Point of Contact

We give every student a dedicated Programme Coordinator. They are your single point of contact throughout the course. Any questions about the programme, the technical information, or working in the industry – it all goes to them.

Personal Trainer

You’ll get one week of course materials released at a time and your Programme Coordinator will manually check your progress at the end of the week. Think of them like a personal trainer for your studies – if it ever looks like you’re starting to fall behind, your Programme Coordinator will reach out and help you put a plan in place for catching up and staying on track.

Online

Learning is 100% online and your study materials are available to you 24/7 – this means you can truly study at the time and place that best suits you. You don’t have to waste time commuting to a classroom and you can take advantage of even the smallest window of available time in your weekly schedule.

No Fixed Class Times

There are no fixed class times – you have the week to complete the topics that you’re given and it’s up to you when you fit that in. You don’t have to quit work, you don’t have to give up precious family time and you don’t need to rearrange any caring responsibilities or previous ongoing commitments.

Support Through Your Job Hunt

We know from over 15-years experience that when you’re changing careers, it’s not just about learning technical details. Figuring out how to successfully job hunt in a new industry takes time and effort. We decided that we’d save you all that uncertainty by creating a dedicated module that walks you step by step through the job hunting process. When we say we take you all the way from knowing nothing about the industry, to your first job – we mean it!

Imagine what having that level of support and accountability does for your chances of reaching your goals… we’re with you every step of the way.

7) Check our references – Student Testimonials

Agnes Hove

Patricia Radulescu

Domagoj Wunderlich

Jessa Reid

Kieran Mac Namara

8) Fees

Many adult learners want to return to education but find it difficult because they aren’t eligible for the Government’s Repayable Tuition Loan.

To help make our programmes accessible to as many people as possible, we operate an interest-free monthly payment plan. Total course fees are spread across the 4-years of study with no additional fees or charges.

This means you don’t have to pay all your fees upfront and you won’t have any debt hanging over you when you’re finished!

PLEASE NOTE – if you already work in the pharma or med device industries, many companies offer funding for employee training. It may be worth discussing this opportunity with your line manager to see if you are eligible for any company financial support.

Price Includes:

- End of week progress checks by us to MAKE SURE you finish the course

- University accreditation by University of South Wales, UK

- Delivered online so you can learn from home (or anywhere) on your own schedule

- Robust job hunting skills course that will seriously help you find a job

- Regular & ongoing access to a dedicated career coaching counsellor

No Hidden Fees

- No application fees

- No registration fees

- No resource/book fees

- No certificate fees

- No interest fees

9 – How to Apply

The application process is as follows:

- You can request more information about the programme – you can receive this via email or you can fill in your details and a member of the team will phone you to talk through you suitability and answer any questions you might have (click the button on the computer or the phone for these choices)

- Once you’re sure this is the right decision for you, you’ll submit registration documentation (NOTE: if you’re already convinced, press the final big red button below and you’ll be taken straight to the registration form)

- When we receive your registration form, we will review your submission and follow up, offering interviews after the application date has passed

- You will then complete both a written and telephone interview

- Once the interviews are concluded, offers will be sent out. Successful candidates will have 24 hours to accept their offer

- The course will then begin on the 30th July

Got More Questions?

Fill out the form below and we’ll get back to you in one working day.

If you’d like to chat with us quickly, click on the blue chat bubble located in the bottom right corner of the page. We usually respond within a few minutes to a few hours.